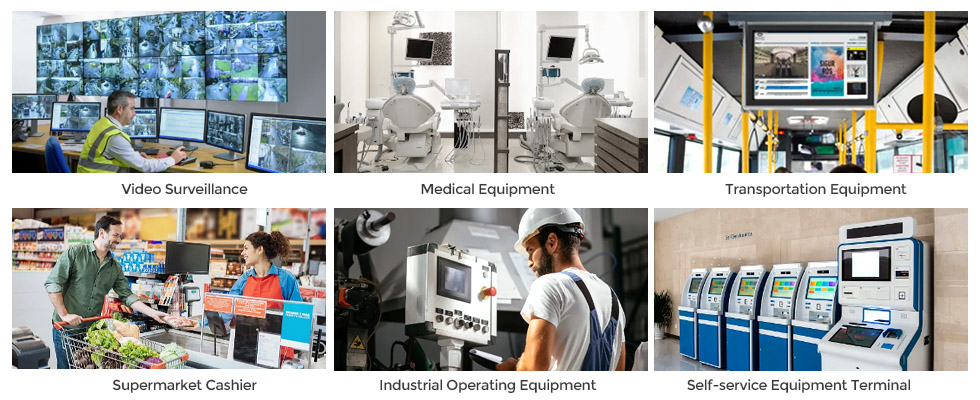

Industrial touch screen monitors are essential for manufacturing, automation, medical equipment, and harsh environments where durability and reliability matter. Unlike consumer-grade displays, industrial monitors must withstand extreme temperatures, dust, moisture, and constant use.

Choosing the right one can be challenging, so this guide covers the “key factors" to consider before making your purchase.

1. Determine the Touch Screen Technology

Different touch technologies suit different industrial applications:

- Resistive Touch:

- Works with gloves, stylus, or bare fingers.

- Durable but lower clarity (not ideal for high-resolution needs).

- Best for factories, medical devices, and outdoor kiosks.

- Capacitive Touch:

- High sensitivity, multi-touch support (great for interactive displays).

- Requires bare fingers (not glove-friendly unless specially coated).

- Used in food processing, cleanrooms, and control panels.

- Infrared (IR) Touch:

- No physical layer, highly durable, and scratch-resistant.

- Works with any input (gloves, stylus, etc.).

- Ideal for heavy machinery, military, and outdoor applications.

- Surface Acoustic Wave (SAW):

- Excellent image clarity and scratch resistance.

- Sensitive to dust and moisture (better for indoor use).

2. Consider Environmental Durability

Industrial monitors must endure harsh conditions. Look for:

- IP Rating (Ingress Protection):

- **IP65: Dust-tight and water-resistant (suitable for wash-down areas).

- **IP67: Can withstand temporary submersion.

- Operating Temperature Range:

- Standard monitors: **0°C to 50°C**

- Industrial-grade: **-30°C to 70°C** (for freezing warehouses or desert use).

- Vibration & Shock Resistance

- Needed for vehicles, mining, and heavy machinery.

3. Choose the Right Display Size & Resolution

- Small (10"–15") – For compact control panels or handheld devices.

- Medium (17"–24") – Common for factory HMI (Human-Machine Interface).

- Large (32"–86") – Used in control rooms, medical imaging, and digital signage.

Resolution matters:

- Full HD (1920×1080) – Standard for most industrial uses.

- 4K (3840×2160) – Needed for detailed graphics (medical imaging, CAD).

4. Check Compatibility & Connectivity

Ensure the lcd screen touch monitor supports:

- Industrial PCs (Windows, Linux, Android, etc.)

- Legacy ports (VGA, DVI) or modern (HDMI, DisplayPort, USB-C)

- Protocols (Modbus, CAN bus, RS-232 for machinery integration)

5. Evaluate Longevity & Support

- MTBF (Mean Time Between Failures):Look for 50,000+ hours.

- Manufacturer Warranty: Industrial monitors should have 3–5 years.

- Replaceable Parts: Some industries need modular designs for easy repair.

Conclusion

Selecting the right industrial touch screen monitor depends on touch technology, durability, size, resolution, and compatibility. Assess your environment, required lifespan, and interaction needs before purchasing.