Selecting the correct LCD size is one of the most important decisions when specifying a custom industrial LCD monitor. In industrial environments—where reliability, visibility, ruggedness, and usability define productivity—choosing between 7-inch, 10.1-inch, and 12-inch industrial displays requires careful evaluation. Each size offers unique advantages depending on the application, available panel space, and operator interaction requirements.

This guide provides a detailed comparison of 7″ vs 10.1″ vs 12″ industrial monitors, including their pros, cons, ideal use cases, and key specification considerations to help you select the right display for your custom industrial system.

Before comparing sizes, it’s critical to understand the broader considerations that affect industrial display performance.

Environment & Durability

Temperature range

Shock/vibration rating

IP rating / waterproofing

Ingress protection for dust and chemicals

Touchscreen Requirements

Resistive touch for gloved operation

Projected capacitive (PCAP) for gesture control

Anti-glare / anti-fingerprint coatings

Brightness & Readability

High brightness (1000+ nits) for outdoor sunlight

Wide viewing angles

Optical bonding for better contrast

Electrical & Control Interface

LVDS, eDP, HDMI, VGA, DisplayPort

Serial or USB touch interface

Custom OSD or firmware options

Mounting & Mechanics

Panel mount

VESA mount

Open-frame or enclosed housing

Once these criteria are defined, size selection becomes clearer.

A 7-inch industrial display is one of the most widely used small-format screens in industrial and embedded systems.

Compact footprint ideal for tight enclosures or handheld devices

Lower power consumption compared to larger displays

More cost-effective for high-volume applications

Sufficient for simple HMI interfaces, button layouts, or data readouts

Lightweight and easy to integrate into mobile or portable equipment

Limited screen real estate for complex dashboards or multi-window UIs

Smaller fonts may reduce readability in harsh environments

Not ideal for detailed schematics, diagnostics, or data-heavy UIs

Handheld controllers

Portable diagnostic devices

Compact industrial machinery

Basic HMI panels

IoT gateways and embedded control systems

A 10.1-inch LCD display strikes a balance between compact size and usable workspace, making it one of the most versatile industrial panel sizes available.

Optimal size for modern HMI/SCADA interfaces

Good balance between visibility and enclosure size

Supports multi-touch PCAP functionality comfortably

Suitable for video, graphics, and detailed data visualization

Still relatively low power consumption compared to 12″+ models

Larger enclosure footprint vs. 7″

Higher cost

May still be slightly small for high-density control rooms or complex dashboards

Fixed industrial HMI panels

Factory automation consoles

Equipment status monitoring

Medical devices requiring a compact but clear UI

Industrial kiosks and control terminals

A 12-inch industrial monitor provides ample visual real estate for larger, more complex interfaces.

Large display area for detailed information

Excellent readability for operators at a distance

Ideal for multitasking interfaces or advanced diagnostics

Supports higher resolutions (WXGA, SXGA) for enhanced UI clarity

Better ergonomics for control rooms and operator stations

Larger physical size requires more mounting space

Higher power consumption

Higher overall cost

May be oversized for small machinery or embedded systems

Heavy industrial automation

Control room operator panels

Advanced HMI/SCADA dashboards

Marine, transportation, or mining equipment

Environments requiring high visibility

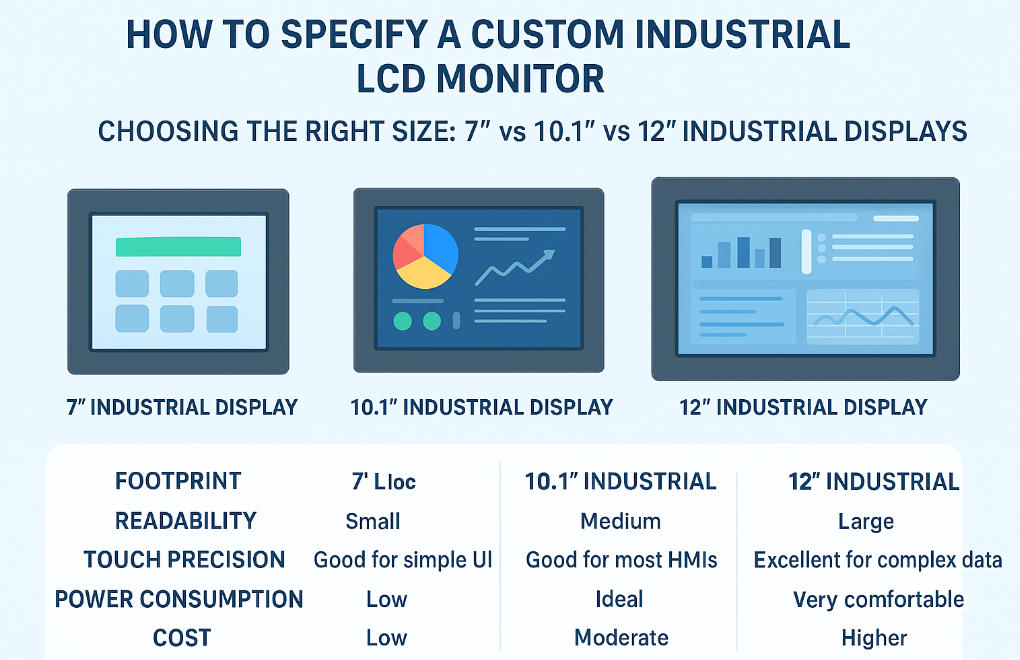

| Feature | 7″ Display | 10.1″ Display | 12″ Display |

|---|---|---|---|

| Footprint | Small | Medium | Large |

| Readability | Good for simple UIs | Good for most HMIs | Excellent for complex data |

| Touch Precision | Limited for complex layouts | Ideal | Very comfortable |

| Power Consumption | Low | Medium | Higher |

| Cost | Low | Moderate | Higher |

| Best For | Compact/embedded systems | General industrial HMI | Professional control stations |

Selecting the right size depends on how the monitor will be used and the environment in which it operates.

Space is highly limited

You only need simple functions or basic data readouts

The device is handheld or portable

You want the best balance of size, usability, and cost

The HMI interface includes multiple widgets or graphical data

You need a modern touchscreen experience

You require maximum visibility and ergonomic operation

Operators need to view complex processes or diagnostics

The installation environment supports a larger enclosure

Choosing between 7″, 10.1″, and 12″ industrial LCD monitors depends on your operational needs, environmental constraints, and interface complexity.

A 7-inch screen is compact and efficient, a 10.1-inch display is the most versatile option for modern industrial HMIs, and a 12-inch monitor offers superior readability for advanced industrial applications.

When specifying a custom industrial LCD monitor, consider not only the size but also environmental durability, touchscreen type, brightness, interface compatibility, and mechanical integration. By selecting the right display size and configuration, you ensure improved usability, long-term reliability, and optimal performance in your industrial system.